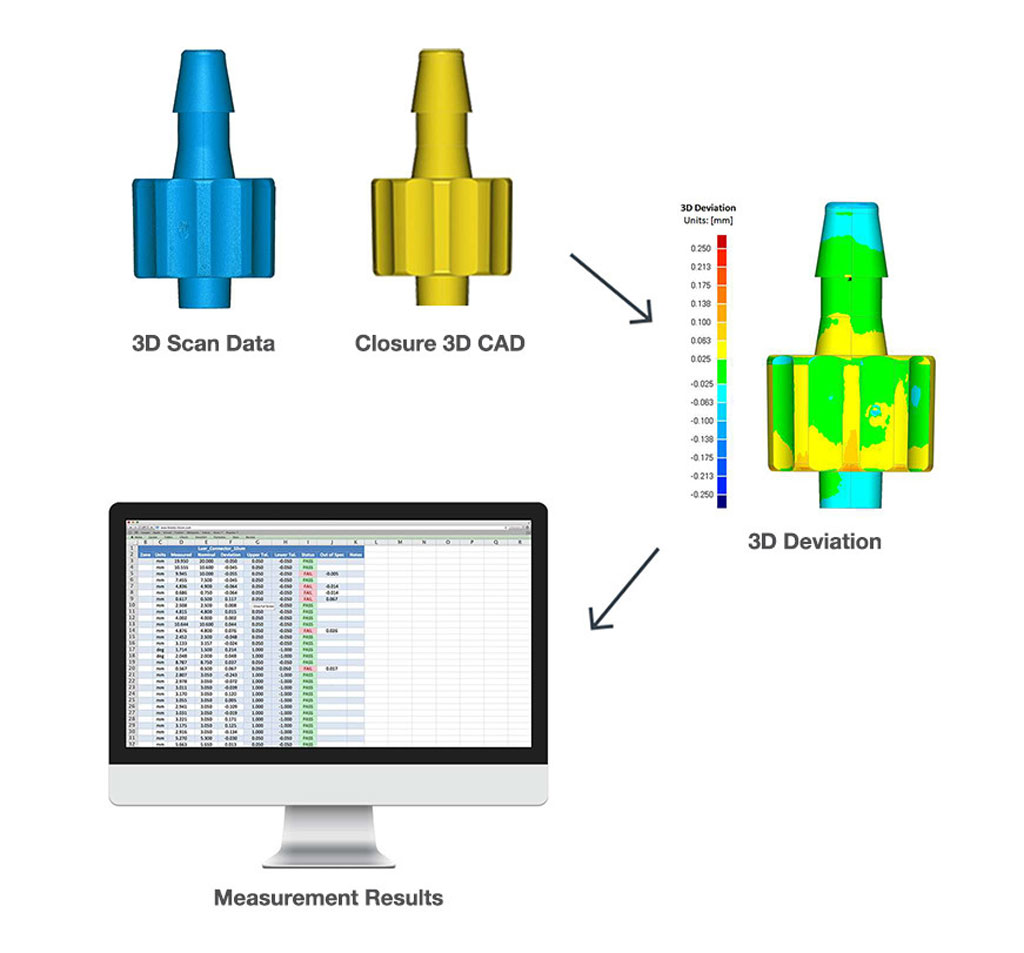

Kinetic Vision's ISO 9001-certified 3D Metrology services non-destructively and accurately measure component internal and external dimensions, surfaces and features. Many production issues arise because of difficulties confirming that manufactured parts meet the design dimensions and tolerances, and the problem is made harder when complex shapes are involved as traditional measurement techniques are insufficient. Our in-house 3D CT Scanning provides the data point quantity and accuracy to allow Part-to-CAD and Part-to-Part studies to be quickly done, with results presented as simple measurements, Geometric Dimensioning and Tolerancing (GD&T) variation, or 3D deviation.

Complex high-cavitation biomedical parts containing critical internal features that are not easily captured using traditional inspection methods can now be quickly and accurately measured leveraging scanning-based 3D Metrology. Full part inspection and validation can now be completed in a fraction of the time and cost of older technologies, allowing for faster Production Part Approval Process (PPAP) and First Article Inspection (FAI).

Injection Molded Medical Part 3D Metrology

A medical manufacturer was experiencing quality issues in the field with a molded component and didn't have the in-house expertise to verify the dimensional accuracy of the as-manufactured geometry. Using a 3D CT scan Kinetic Vision was able to measure the part features with high accuracy and make a statistical comparison to the CAD model. Part vs. CAD total deviation color graphics were also used to enable a more visual understanding of the 3D metrology results.