3D Printing – No Longer Just For Rapid Prototyping

Published Wednesday January 3, 2018

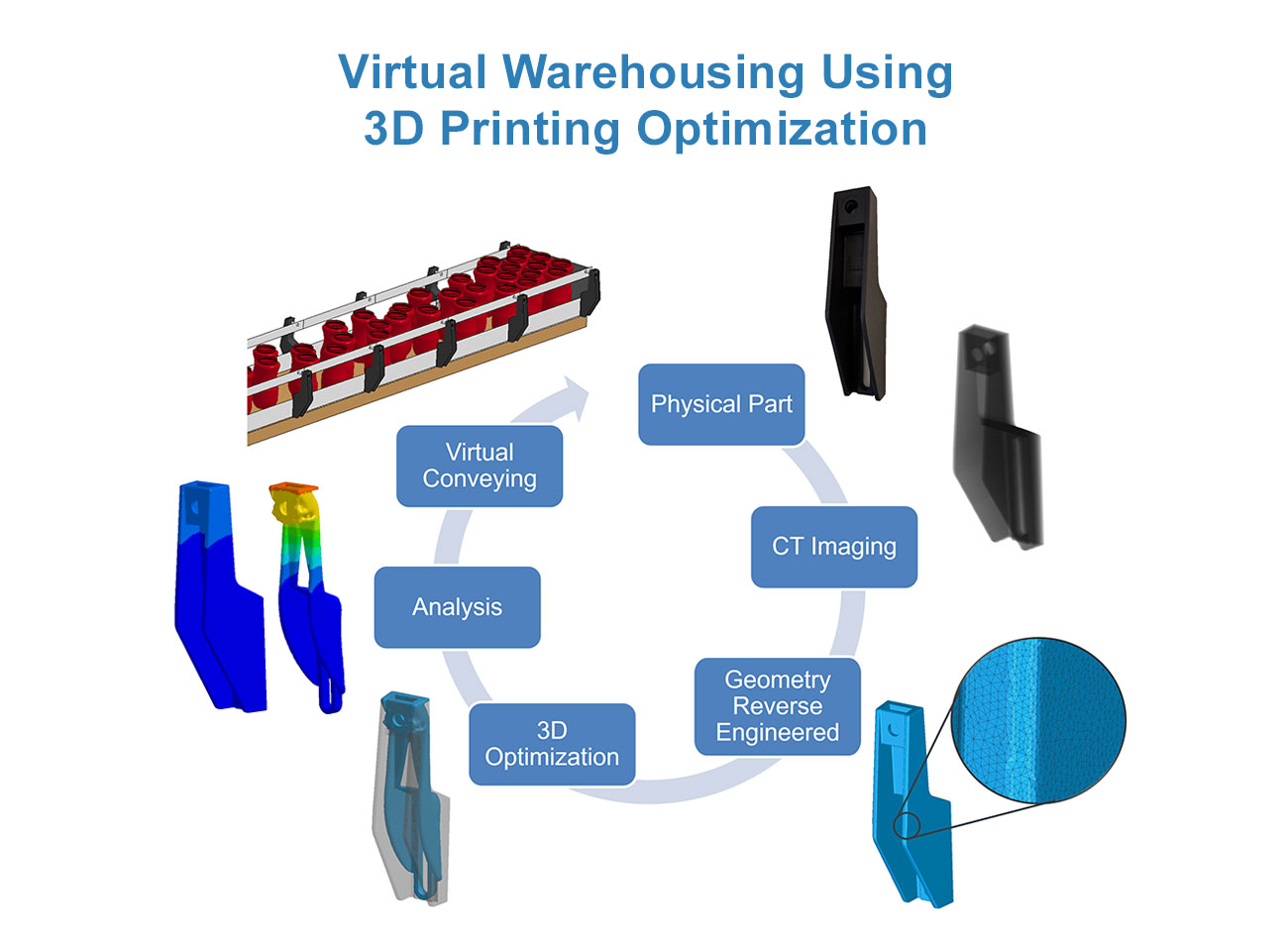

On-Demand 3D Printing of Factory Change Parts – Virtual Warehousing

Modern manufacturing lines are designed to make the product changeover process as efficient as possible. This process usually involves machinery adjustments and the replacement of “change parts”, which are unique, non-adjustable equipment components that must be updated for the new product. For production lines that create many different products, or several variations of the same product, stocking the dozens or hundreds of change parts required can become unmanageable and inefficient. This problem is exacerbated when production lines contain legacy components where manufacturing data or drawings no longer exist or are controlled by another company.

On-demand 3D printing creates opportunities for eliminating the change part stocking problem. Instead of stocking physical parts for every possible production scenario, only the digital data need be cataloged. Critical change parts are created as needed in less than a day. On-demand additive manufacturing also eliminates production issues caused by part wear or improper design revision level, as modern PLM systems ensure consistent design integrity from engineering through production. CAD data for legacy components are easily created using 3D CT Scanning, and Modeling and Simulation is utilized to optimize the part design for minimum material and build time. Learn more about Design for Additive Manufacturing.