Our story

Kinetic Vision started as a one-person consulting firm specializing in computer simulation of components and systems. Since then, we’ve grown to become one of the premier product and technology development firms in the United States, servicing over 50 of the Fortune 500 companies. Our expertise spans several vertical markets, including medical, transportation, consumer packaged goods, food and beverage, electronics, aviation, and more. Now, more than 30 years later, our clients leverage Kinetic Vision’s collaborative, multidisciplinary teams to solve tough challenges in all areas of the product life cycle.

Your advantage

When you work with Kinetic Vision, you quickly realize the power of working with an experienced team of technologists, engineers, strategists, planners, and creatives who bring cross-collaborated learning from multiple industries. Some of the areas we work in include:

- Product Engineering

- Packaging Innovation

- Product Quality Engineering

- Smart Products and Embedded Development

- Medical Device Development

- Software Applications

- Data Engineering

- AR/VR/XR Applications

- Digital Twin Simulation

- Industrial Scanning and Analysis

- Visual Communication

- Artificial Intelligence

- Synthetic Data

Our breadth of expertise and full suite of software and hardware tools helps our clients meet their complex product and system development challenges with efficient concept-to-production solutions.

The Industrial Metaverse™

Integrating digital twins throughout the product life cycle into the Industrial Metaverse.

The industrial metaverse is here – and it’s changing how products and services are conceived, developed, and implemented. Simply put, it’s the unification of every process throughout the product life cycle, from product ideation, design, engineering, manufacturing, quality control, sales and marketing, market research, distribution logistics, through end-use. Digital tools exist today for many of these processes, but they are fragmented into different organizations, in different facilities, and even different countries. That’s about to change. Take a look at the video below:

The Industrial Metaverse will break down walls and barriers – and processes will be integrated into virtual three-dimensional environments that enhance collaboration and democratize data. Stakeholder communication will transform from 3D to 4D, as virtual environments will be photorealistic and navigable. Products and systems will function virtually, allowing for rapid testing and optimization. If you want to know more, please Contact Us and we’ll give you a guided tour!

Our difference

No other company has the breadth of expertise under one roof that we do, and those multidisciplinary skills allow us to solve seemingly impossible problems and create innovative products and systems that others cannot.

Our "one-stop shopping" model creates a simpler, unified customer experience, with efficiencies that produce significant time and cost savings when compared to traditional multi-vendor approaches.

The Innovation Center

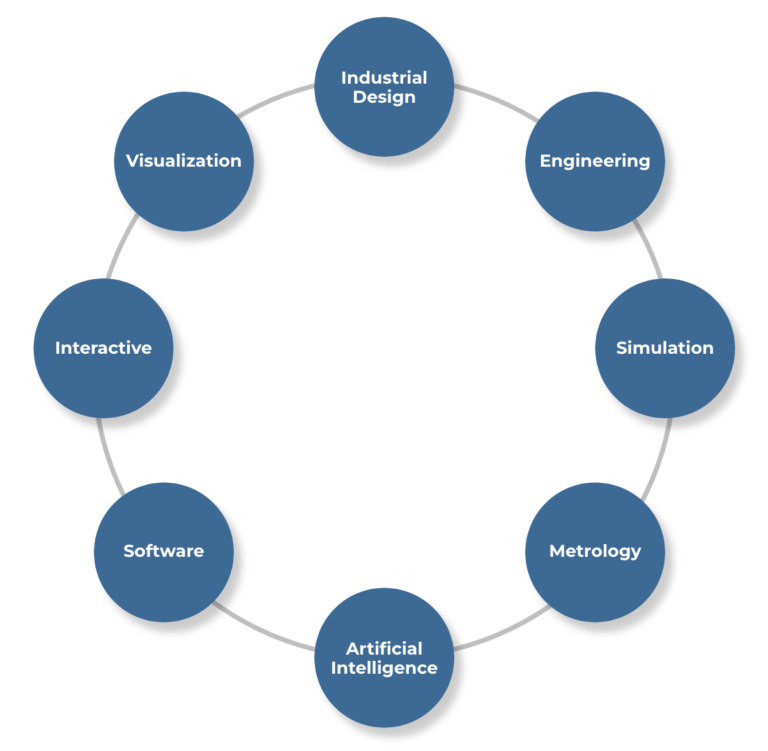

In the summer of 2022, we moved to our new headquarters in the Aerohub innovation District in Cincinnati, Ohio. Our custom-built facility combines all the resources of our previous three-building campus into one state-of-the-art facility (51400 sf) that is designed to foster innovation at unprecedented speeds. With ample space for both digital and physical development, the Innovation Center optimizes performance by synergizing our eight area of expertise: Industrial Design, Engineering, Simulation, Metrology, Artificial Intelligence, Software, Interactive, and Visualization. In addition, the facility will also bring new upgrades to our rapid prototyping capabilities, Which includes CNC matching, injection molding, laser cutting, advanced 3D printing, vacuum forming, blow molding, in-house PCB production, and more.

Equal Opportunity Employer | Terms of Use

Accept