What Finite Element Modeling?

Finite Element Modeling (FEM), also known as Finite Element Analysis (FEA), is a numerical method utilized to predict the performance of structural, thermal, fluid, electromagnetic and other physical systems. The method requires that the component being studied be broken into discrete elements, resulting in a finite element mesh. The simple equations that describe the individual elements' behavior are then assembled into a larger system of equations that models the entire problem. Depending on whether nonlinear effects are present the resulting system of equations is solved with a direct or iterative solver.

The beginnings of the finite element method can be traced back to the early 1940's in the US, with further developments in the 50's and early 60's in China and the USSR. Generalized software programs didn't become available until 1968 with the introduction of the NASA-sponsored NASTRAN, which is an acronym formed from NASA STRucture ANalysis. Today many comprehensive FEA packages are available, including several versions of NASTRAN, and many others: ANSYS, ABAQUS, HyperWorks and LS/DYNA to name a few.

Accuracy of FEA results are dependent on many factors, including the refinement of the finite element mesh, type of elements utilized, knowledge of the FEA Material Properties, knowledge of the actual loading conditions, and ability to accurately model the physical problem. Kinetic Vision's FEA services group utilizes multiple quality control systems, including QA checklists and peer review.

Learn more about the finite element method at Wikipedia.

Kinetic Vision's FEA capabilities utilize the latest modeling and simulation tools to predict stress, strain and deflection due to static loading. Stress analysis is essential when product quality is related to component deflection or failure due to static or repeated loading. Many problems have important nonlinear characteristics, including material elastic-plastic behavior, nonlinear stress-strain relationships, large deflections and contact between surfaces. It is up to the experience of the simulation analyst to ascertain whether some or all of these effects should be considered. The ultimate goal of our FEA services are to optimize the design to exceed any performance criteria prior to physical testing and performance verification.

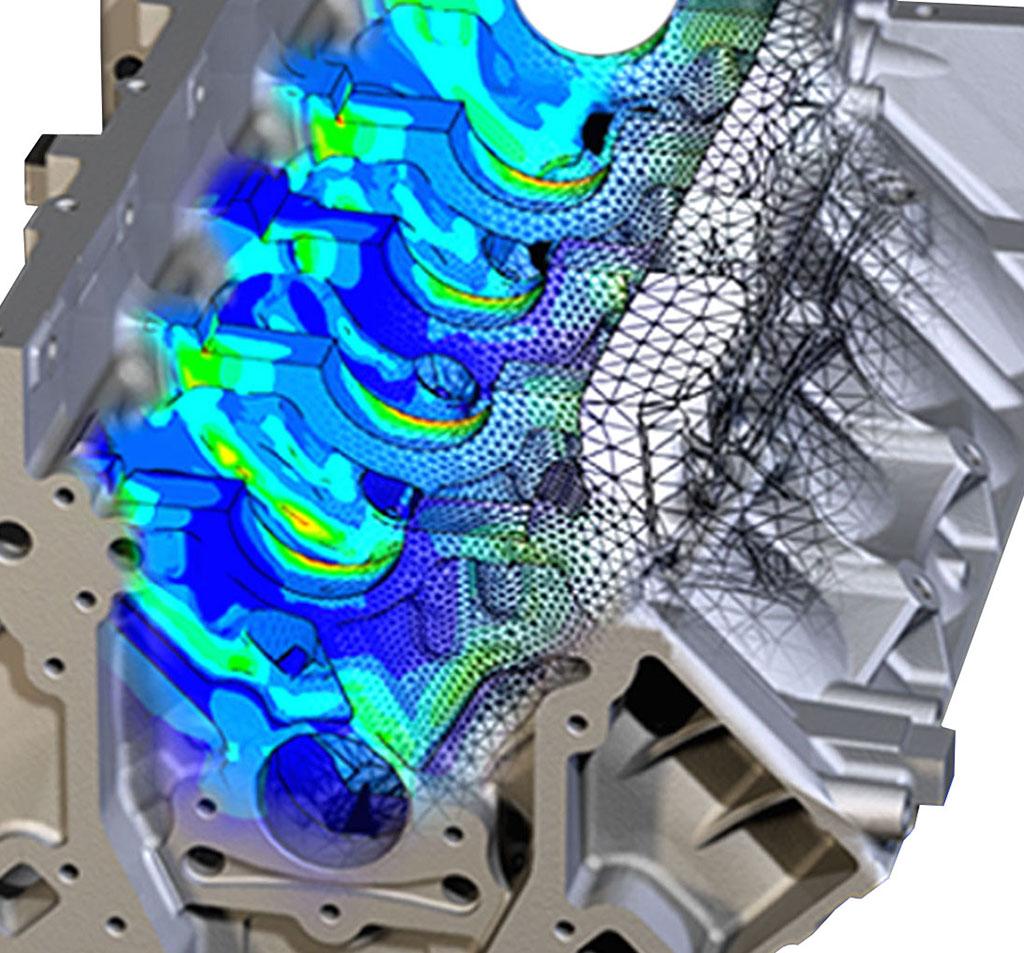

Engine Block Bearing Support Deflection

In this example a finite element analysis was done to predict the engine block main bearing support wall deflections due to manufacturing loading. The wall deflections affect the material removed during the broaching process, which in turn affects the final bearing system concentricity and overall product quality.

Learn more about our Modeling and Simulation capabilities.