What is Industrial Digitalization?

Industrial digitalization is the process of accumulating and centralizing all the data and information about your facility, processes, and procedures into one visually-enhanced data source. Maybe you have a legacy facility and want to document spaces, equipment, and processes that were installed decades ago. Or you've built a new facility and need a three-dimensional "as built" understanding that 2D construction drawings don't convey.

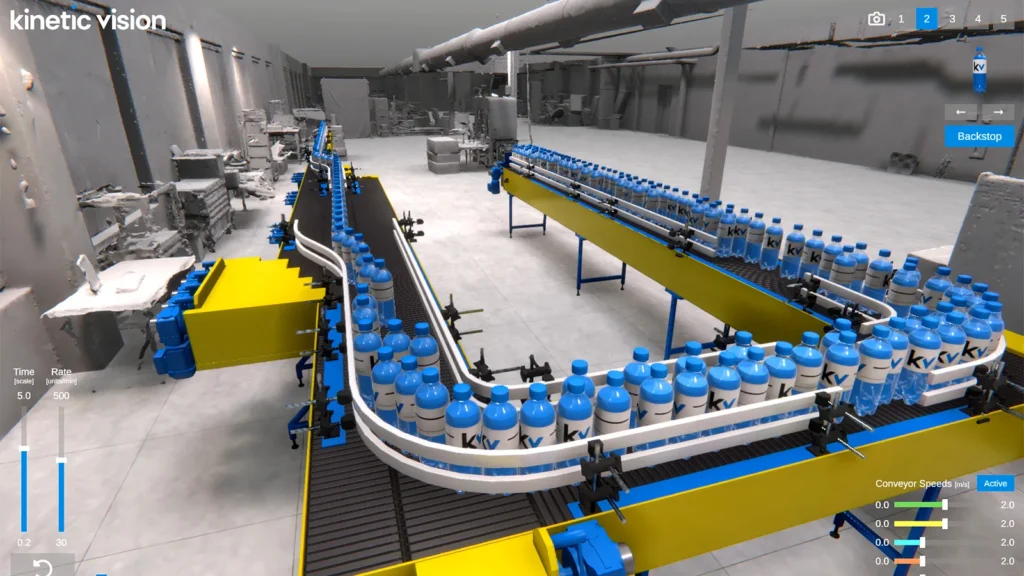

Once your facility is scanned and activated, it’s easy to tag and add descriptions to key equipment, modify configurations, or lay out totally new systems. You can even connect and monitor important processes within the 3D knowledge base. Plus, our simulation and software experts can help you create a true digital twin, complete with functioning equipment and systems. This empowers you to virtually optimize existing processes, design new ones, or even develop and implement AI systems with dramatic time and cost savings. Our use of the NVIDIA Omniverse advanced visualization and collaboration platform, and real-time game engines like Unity and Unreal Engine, enables us to create industrial digital twins that are both visually realistic and functionally accurate.

Industrial Digitalization with our Acquire ▸ Activate ▸ Optimize process makes it easy.

Acquire

Gather scan data quickly and learn fast. We've partnered with NavVis, whose VLX mobile scanning system is up to 10 times faster than using a terrestrial laser scanner. Their unique SLAM technology delivers global accuracy down to 5 mm, with survey-grade point cloud quality. Acquisition examples include virtual tours, facility audits, and space claim explorations.

- Quickly scan most equipment, systems and facilities in 1-2 days

- No impact to running processes or production

- Interior and exterior survey-quality accuracy down to 5 mm

- Point cloud conversion to an accurate 3D polygonal model

Activate

The activation phase converts the captured scan data into a 3D model. AI is utilized to segment important machinery and equipment from the facility structure. Simple integration of external CAD and BIM gives you the power to virtually design, document, edit, and share data, enabling easy collaboration with key stakeholders.

- Mesh segmentation and tagging/descriptions of key components

- Easily reconfigure layouts with two-way CAD/BIM integration

- Avatar and vehicle circulation analysis and optimization

- Create training and safety videos virtually without onsite production

Optimize

You’ve created an accurate 3D representation of your facility, enabling you to easily modify existing layouts or design new ones, but there’s much more you can do. Our simulation and software experts can help you create a true Digital Twin, complete with functioning processes and systems. In addition, synthetic data can be generated to train AI models, which can then be deployed and evaluated within the virtual twin. This empowers you to virtually optimize existing processes or test new systems, with dramatic time and cost savings.

- Create true digital twins with functional systems, software and virtual IoT

- Troubleshoot and optimize processes with real-time simulation

- Utilize synthetic data for AI system training, testing and optimization

- Run virtual pilot production to find and fix problems before they even exist

Industrial digitalization sounds complicated, and it can be. It requires expertise in mobile scanning, 3D data conversion, model segmentation and manipulation, CAD, industrial engineering, and even software and AI model development. That usually requires working with 3-4 different companies, or just one – Kinetic Vision. If you’re interested in discussing how digitalization can streamline your operations and drive efficiency in your organization, please reach out and one of our experts will contact you right away. You can also learn more about our work on the next-generation data center in this NVIDIA blog article.