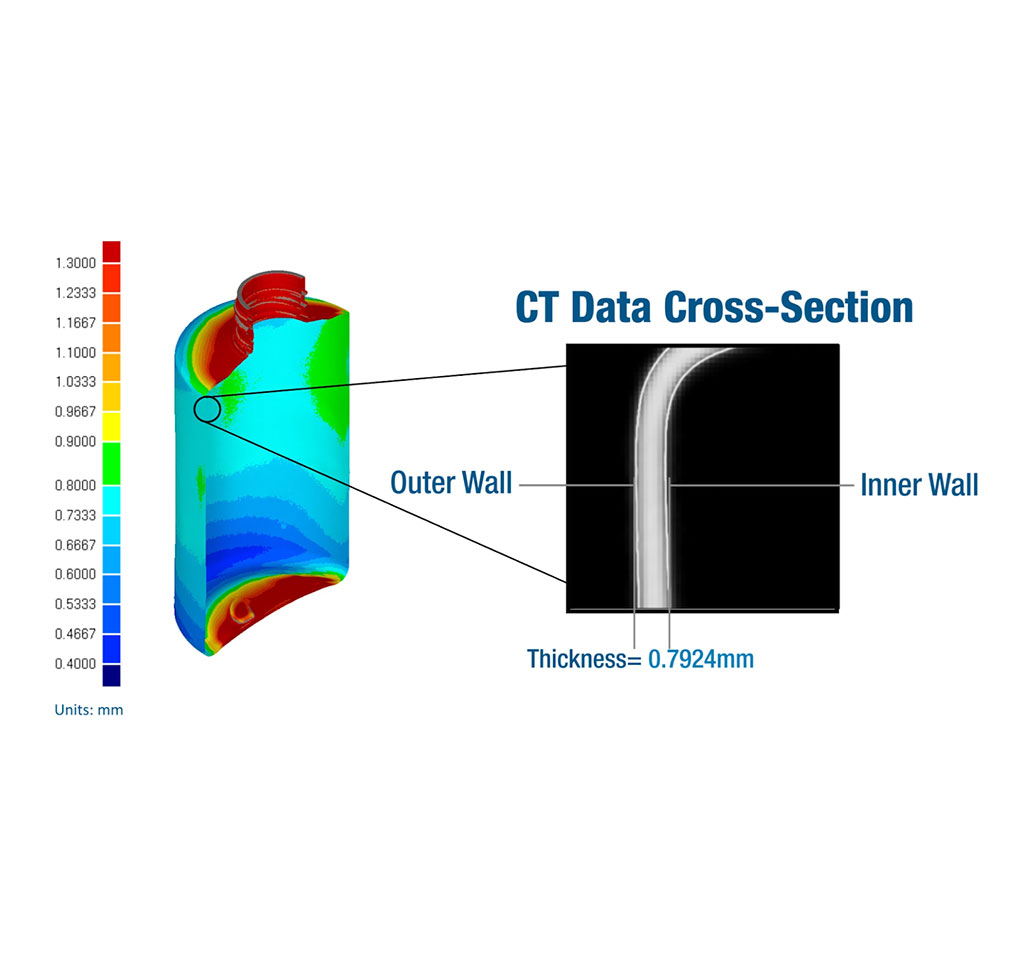

Wall thickness analysis, made possible with 3D CT Scanning, is a powerful measurement technique which allows you to measure and visualize thickness and material distributions across a part. This is especially useful for blow molded products where thickness distribution plays an important role in minimizing production cost and ensuring part integrity. Often used in material optimization studies, wall thickness studies are also valuable for evaluating the structural integrity and manufacturing accuracy of injection molded parts and thin-wall castings.

In this example a blow molded bottle is being light-weighted, or thickness optimized to minimize part cost while maintaining structural integrity for cap sealing, shipping and packing loadings, and consumer-use scenarios such as drop and crush. In addition to being a design tool, wall thickness analysis is also useful for production process verification and First Article Inspection.

Blow Molded Bottle Light-Weighting Study

Light-weighting, a design process where Modeling and Simulation is used to redistribute material to minimize material volume while maintaining part structural integrity, was used in conjunction with industrial CT scans to reduce the production cost of a blow molded bottle.