Optimize packaging with Lightweighting

Published Monday March 10, 2025Blow-molded packaging often contains more plastic than necessary – leading to higher production costs and increased environmental impact. But what if you could reduce material use without sacrificing product performance?

What is Lightweighting?

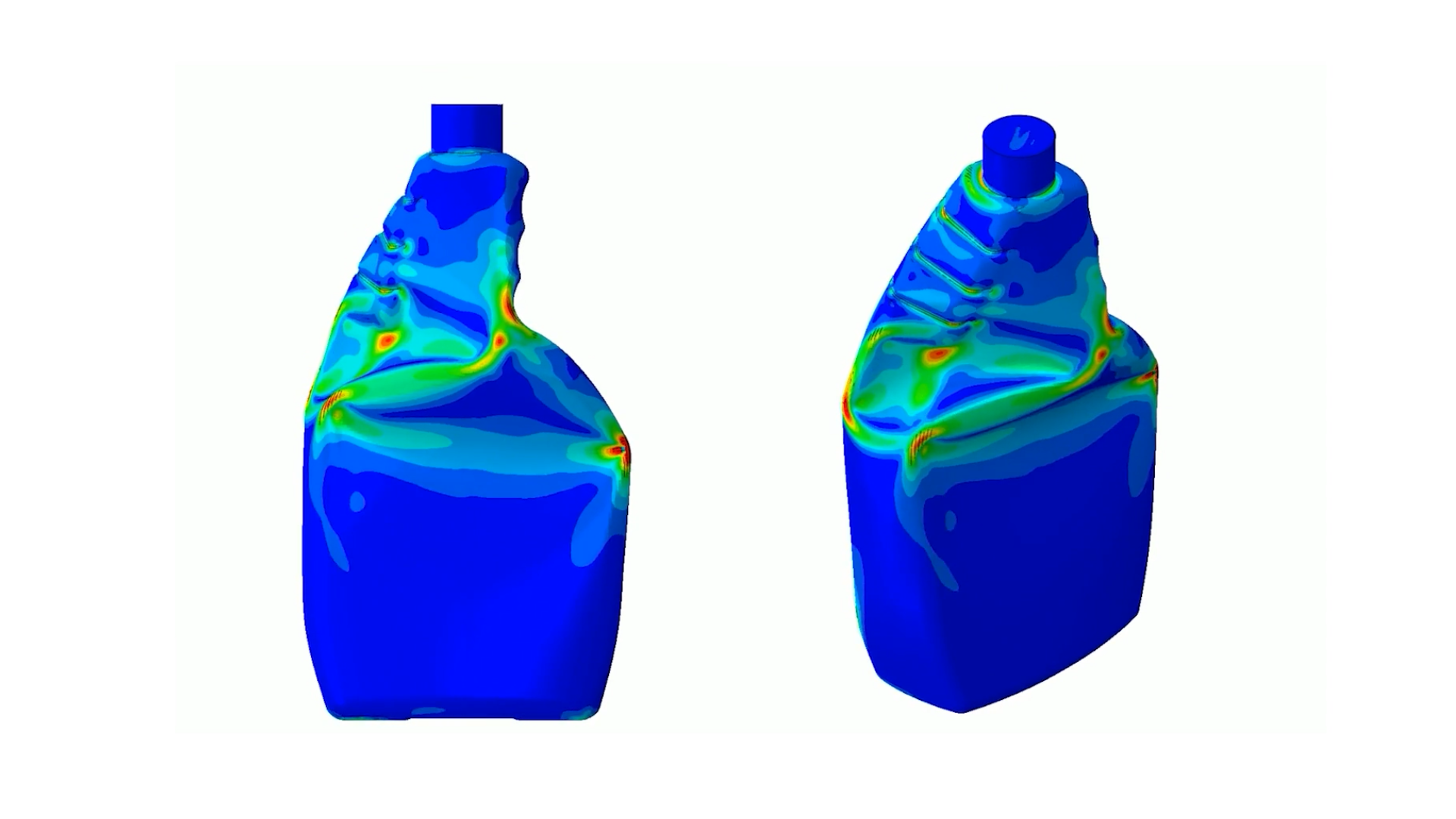

Lightweighting is a proven, simulation-driven process that optimizes material usage in plastic packaging, reducing excess plastic while preserving product performance. Instead of relying on trial-and-error testing, our advanced engineering simulations analyze structural integrity, stress points, and material distribution to precisely determine the minimum material needed without compromising durability or function.

This data-driven approach allows brands to achieve significant material reductions, often 20-30%, with little to no tooling modifications. The result? Lower production costs, improved sustainability, and optimized packaging performance – all without sacrificing product quality or safety.

Why leading brands are turning to Lightweighting

By eliminating excess plastic, brands can achieve significant cost savings and sustainability benefits without compromising product integrity:

- Millions in potential cost savings from reduced material use

- Supports brand packaging refreshes, enhancing consumer appeal

- Reduces environmental impact, potentially eliminating millions of pounds of plastic waste annually

- Rapid prototyping – functional samples in just 48 hours for faster decision-making

Lightweighting is already helping brands save millions while minimizing environmental impact – yours could be next. Visit our contact page to explore how Lightweighting can optimize your packaging, lower costs, and support your sustainability goals.