Rapid, accurate, and held to the highest industry standards, 3D laser measurement systems provide precise analyses of the dimensions, contour, curvature, form, planarity, and roughness of your sample - all without risking its integrity. Our structured light scanning services offer a nondestructive, non-contact measurement method that creates high fidelity data applicable to a wide range of disciplines, including 3D Metrology, Reverse Engineering Services, Modeling and Simulation, and Visual Communication. Other benefits of structured light scanning include simple machine calibration, minimal sample preparation, and fast processing time when compared to other more traditional methods. With our fast turnaround, Kinetic Vision's structured light scanning services ensure that your inspection or quality issues are quickly measured, understood and resolved.

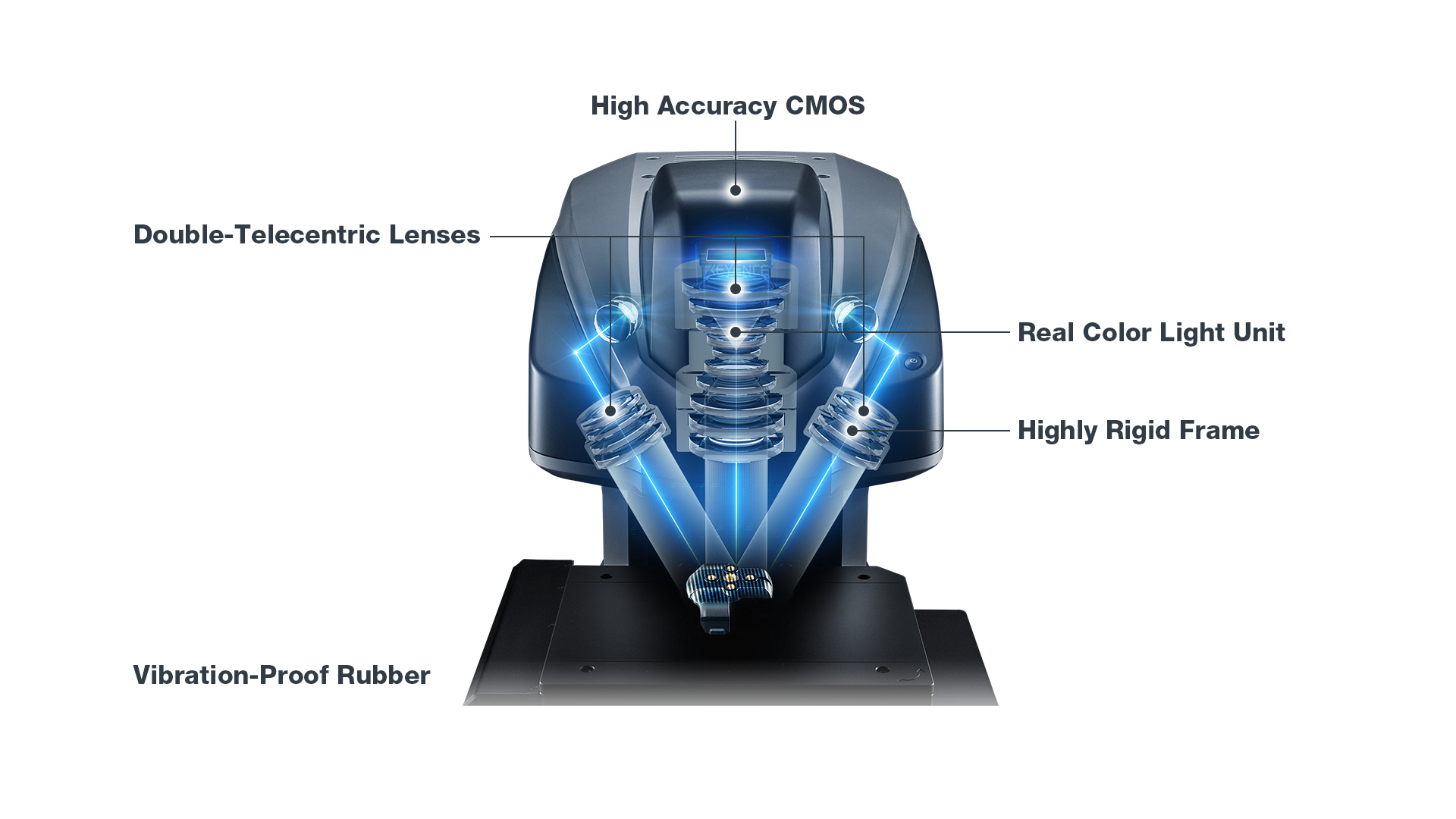

3D Structured Light Scanning and Topography Equipment

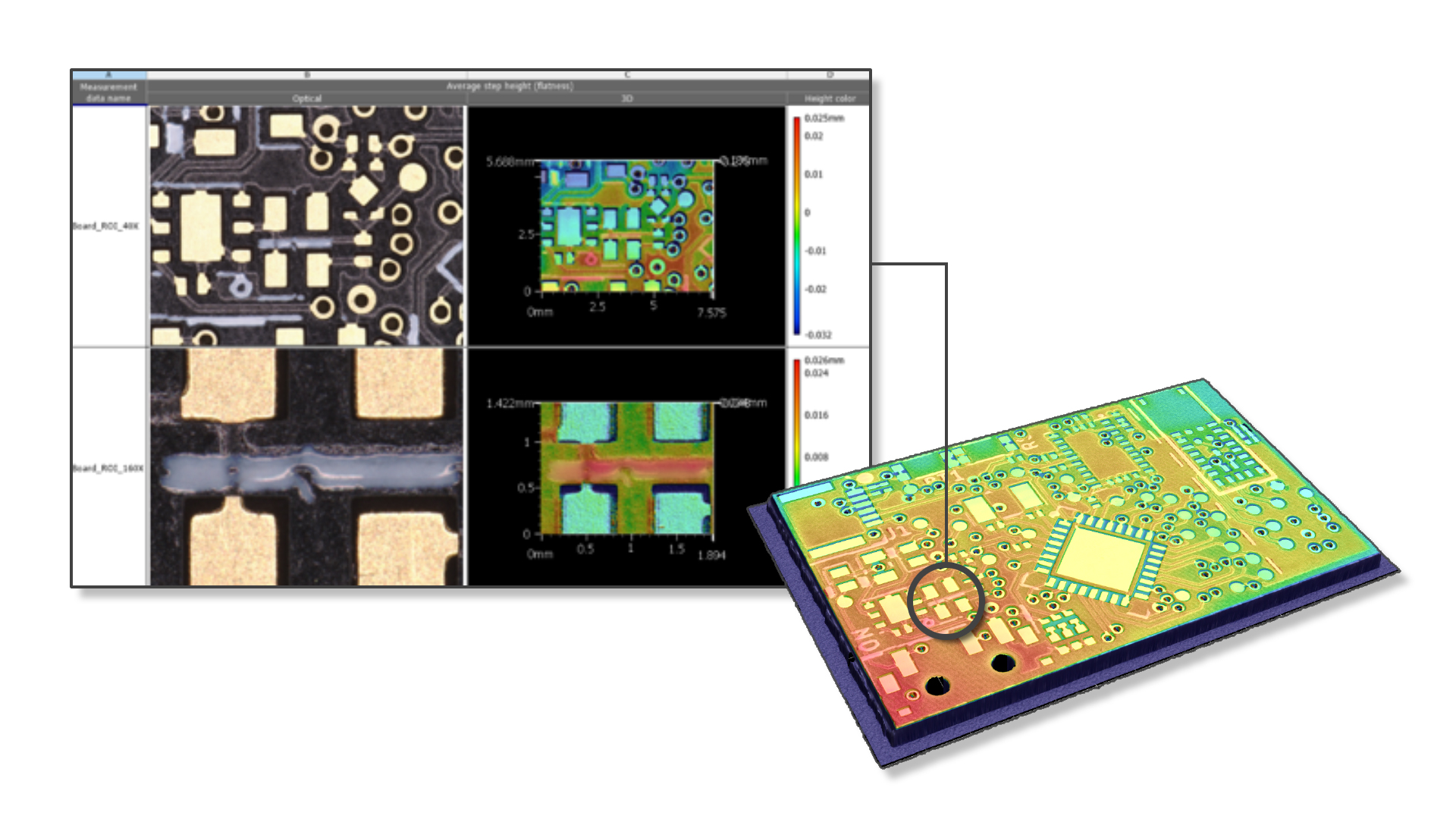

Our structured light scanning systems capture high resolution detail of your product or component via non-destructive acquisition. The system is able to provide precise measurements across 10 dimensions and enables fully automated XY and Z control stitching functions. With its 4-megapixel monochromatic CMOS and double-telecentric transmitter and receiver lenses, it can achieve micron-level accuracy. This allows for nondestructive, non-contact, and high-resolution measurement of the following:

- Height/Flatness

- Form/Contour

- Diameter

- Volume/Area

- Length

- Profile Measurement

- Height Difference/Planarity Measurement

- Volume/Area/Counting

- Curvature, Line/Surface Roughness

- 2D Measurement

High-Resolution 3D Data Acquisition

Structured light scanning is especially valuable in 3D data acquisition. Our system measures the precise dimensions of your specimen, including form, contour, length, profile measurement, curvature, and diameter, providing valuable insights such as area and volume that otherwise might be difficult to calculate. These measurements allow rapid digitalization of physical samples for use in product development, manufacturing troubleshooting, and component quality inspection.

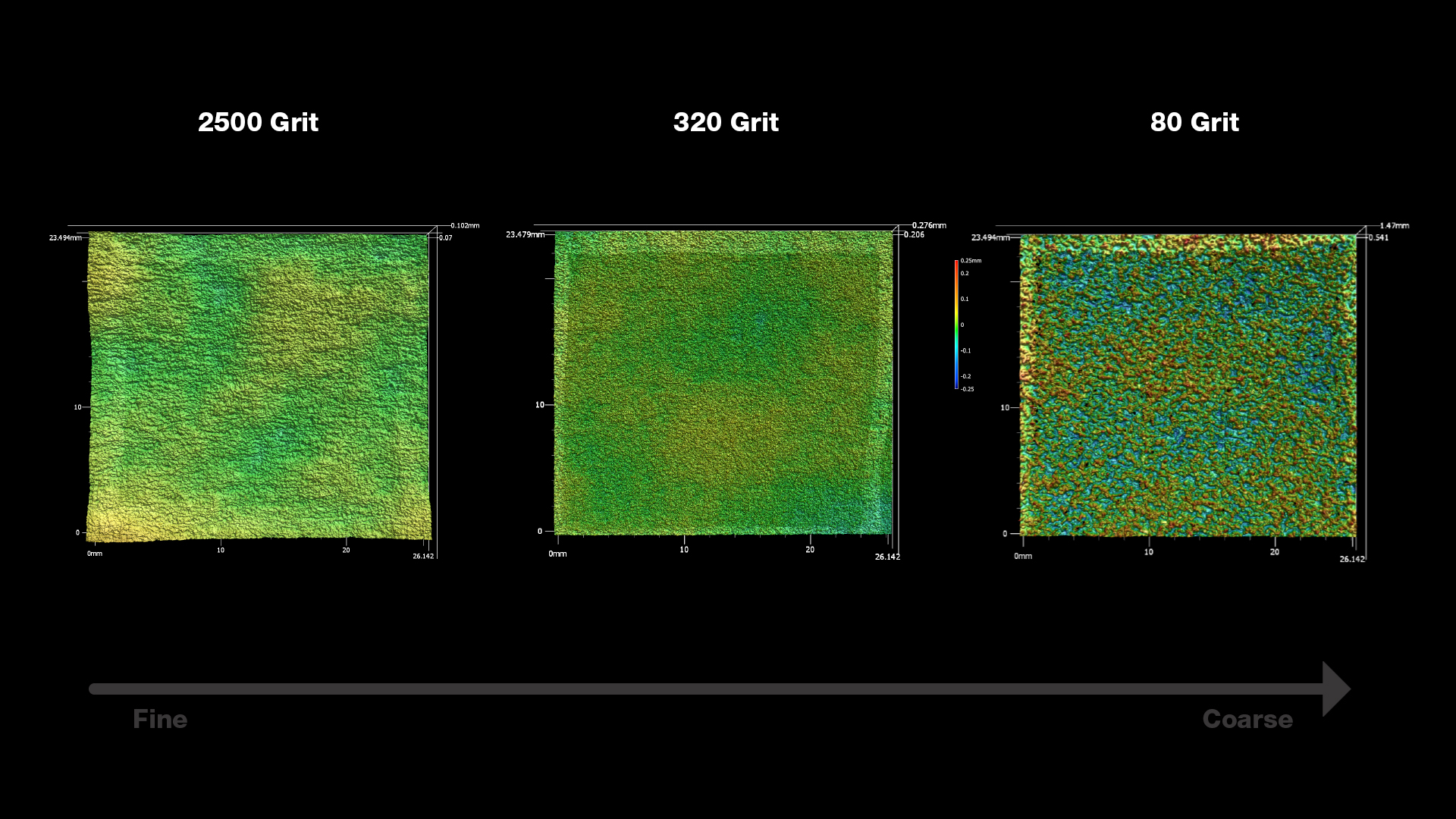

Surface Roughness and Planarity Analysis

With the ability to evaluate 42 different ISO roughness parameters, our structured light scanning services can also analyze superficial variations to calculate the exact roughness of a line or surface. Laser roughness data is both faster to collect and much more exact than data from tactile measurement systems due to physical size limitations of touch probes. In addition, laser systems provide a continuous stream of data rather than the periodically spaced readings inherent in contact measurement.

Structured light data can also be used to calculate component flatness. By evaluating the planarity of discrete points on a surface, laser measurement systems can analyze the levelness of a specimen - a utility especially useful in verifying the flatness of 3D CT Scanning fixture contact points.