Kinetic Vision's Reverse Engineering Services utilize industrial scanners to create a digital model from a physical part, and is often used to create 3D CAD data where manufacturing drawings never existed, are non-digital, or are otherwise unavailable. Point cloud data from 3D Laser Scanning or 3D CT Scanning is utilized by our in-house design engineers to accurately create the part’s internal and external geometry. Customers have many output options: native CAD, polygonal (STL, OBJ, PLY), NURBS model (IGES, STEP, Parasolid), or directly formatted for 3D Printing and Modeling and Simulation.

Learn more about Reverse Engineering at Wikipedia.

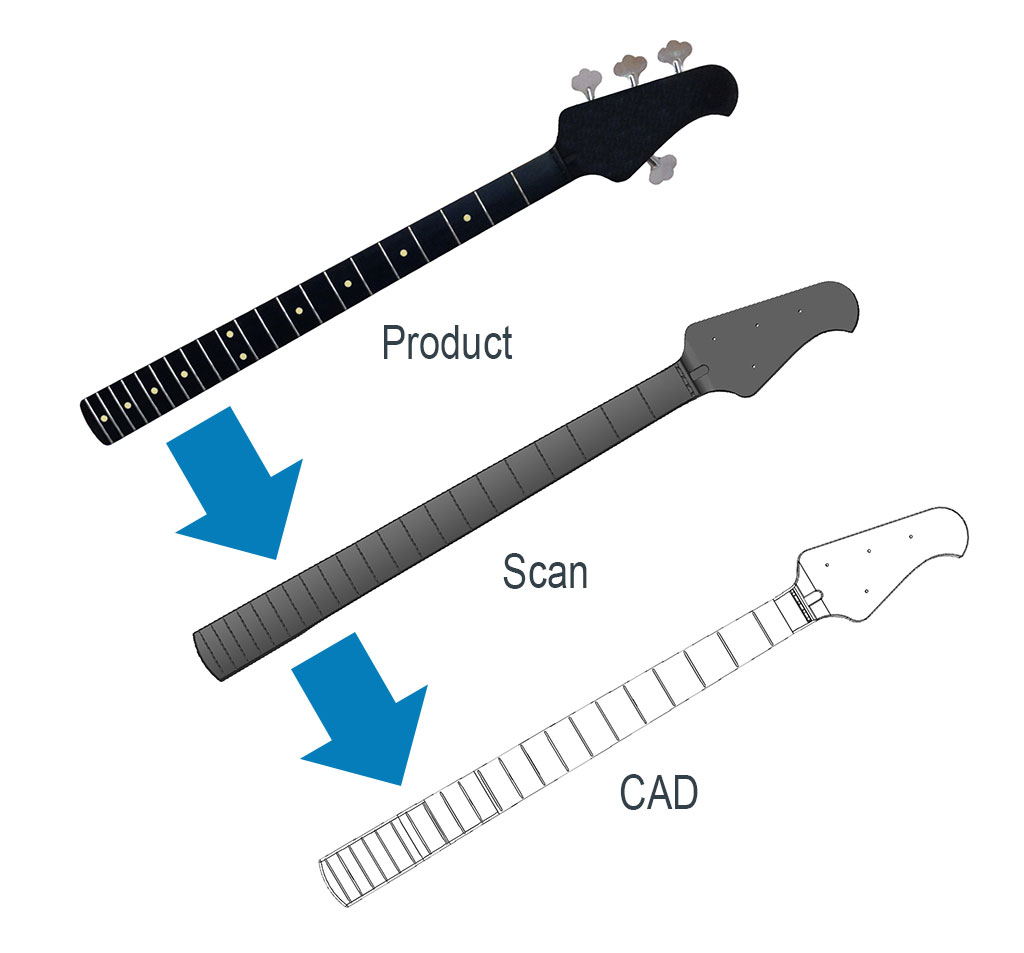

Bass Guitar Neck

Not all imaging needs fit within the standard parameters of typical scanning methodologies. Sometimes parts and components are too large to fit in the scanning envelope, are too difficult to support using standard fixturing, or need to be actuated during the scan. Those challenges require special methods, fixturing and software, and we have the design, engineering and development skills to meet those needs.

High-fidelity 3D CT Scans of a bass guitar neck were done to create a custom instrument CAD database. Due to the high aspect ratio of the part, traditional imaging methods could not be leveraged to capture the data. Kinetic Vision's Reverse Engineering Services group utilized advanced scanning and post-processing techniques to successfully create an accurate three-dimensional digital representation of the physical sample.

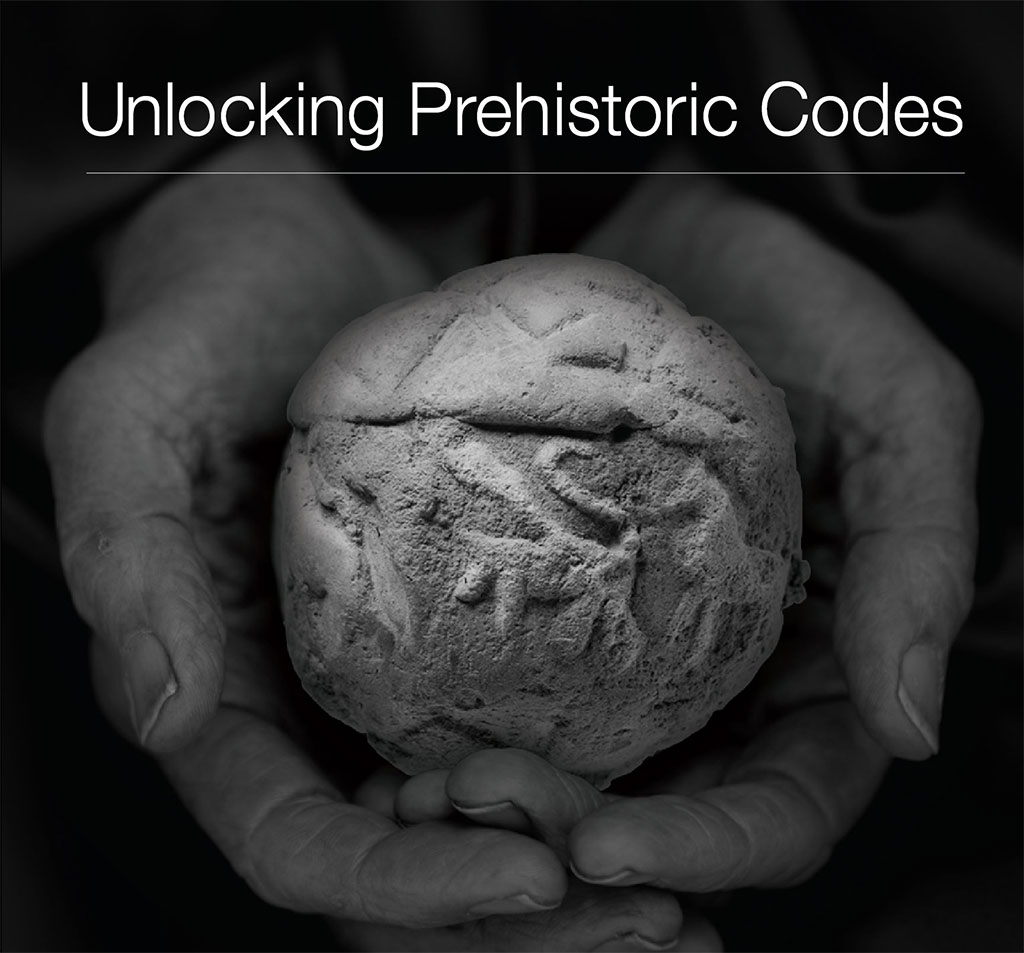

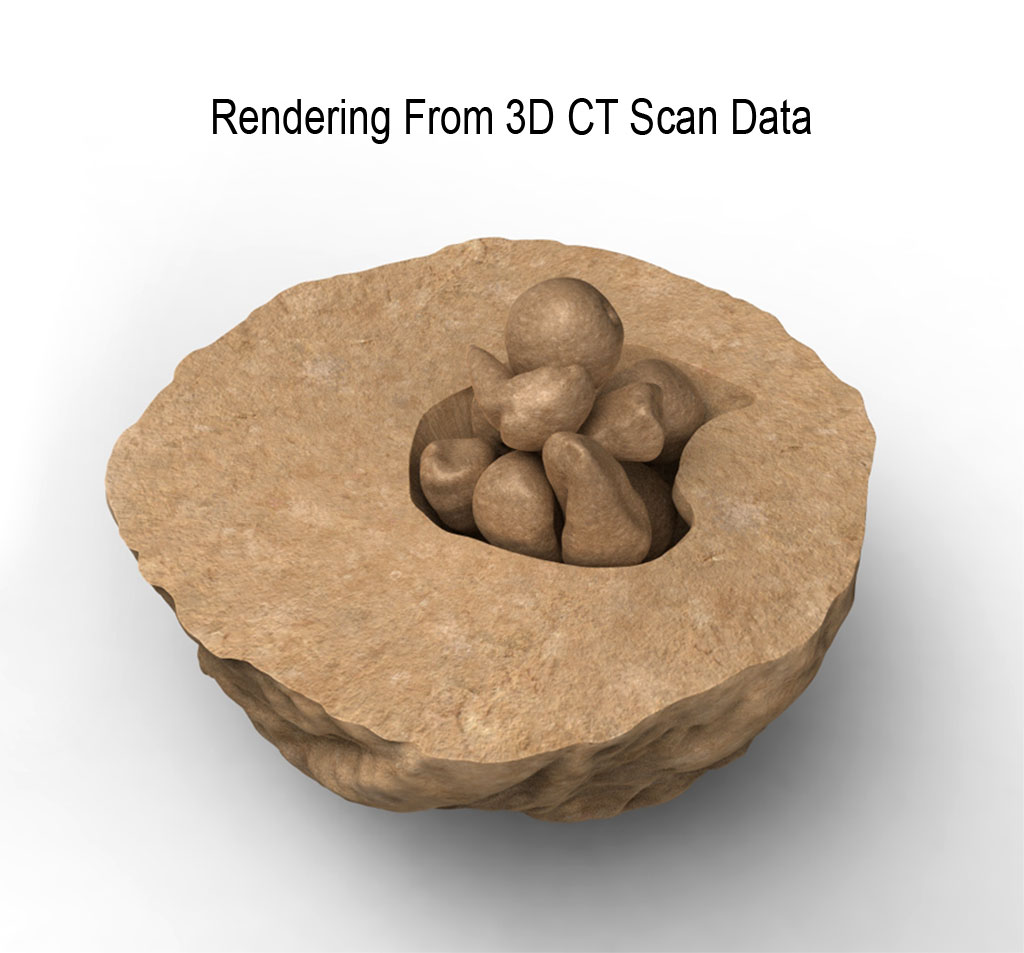

Archaeological Artifacts

Clay balls unearthed in Iran, Iraq and Syria more than 50 years ago are thought to be early administrative devices used to monitor and control the flow of materials, commodities and labor. The balls, or “envelopes”, date back to 3500 B.C. and contain small internal clay artifacts known as “tokens”, which represent the transaction details. The artifacts and are thought to predate the earliest forms of writing by a few hundred years.

Although studied using conventional x-ray imaging in the 1970’s, no accurate three-dimensional understanding of the tokens was known until Christopher Woods, Associate Professor of Sumerology at the University of Chicago, teamed up with Kinetic Vision’s Reverse Engineering Services group to unlock the mysteries of these ancient discoveries.

Eighteen envelopes were scanned using high-resolution 3D CT Scanning systems and post-processed to create accurate 3D CAD models of each envelope and associated internal tokens. The models enabled Dr. Woods to interactively view and measure the envelopes and tokens, resulting in information and discoveries that were previously unknown to the archaeological community.

Download this article by Dr. Woods to learn more.