Medical and Industrial CT Scanning Overview

CT scanning, also called Computed Tomography (CT) or Computed Axial Tomography (CAT), is a medical and industrial imaging technology that creates detailed, three-dimensional (3D) representations of human anatomy or industrial components. The term "CT scan" often refers to X-ray CT, because it is the most commonly known form. But many other types of CT exist, such as positron emission tomography (PET) and single-photon emission computed tomography (SPECT). Like traditional radiography, computed tomography scanning relies on an X-ray source and a series of detectors, but instead of a single image, hundreds or thousands of images are taken from different angles to produce cross-sectional (tomographic) slices of the object. These slices consist of grey-scale images that can be computer-processed to produce a complete 3D representation.

Since its introduction in the 70's, CT scanning has been a powerful medical imaging tool for the head, lungs, heart, abdomen, pelvis and extremities, and useful for diagnoses of disease, cancer, bone fractures and other conditions. Industrial CT is a form of nondestructive testing (NDT) utilized for the inspection and measurement of industrial components and products.

Learn more about CT scanning at Wikipedia.

Courtesy of the National Institute of Biomedical Imaging and Bioengineering

Industrial CT Scanning

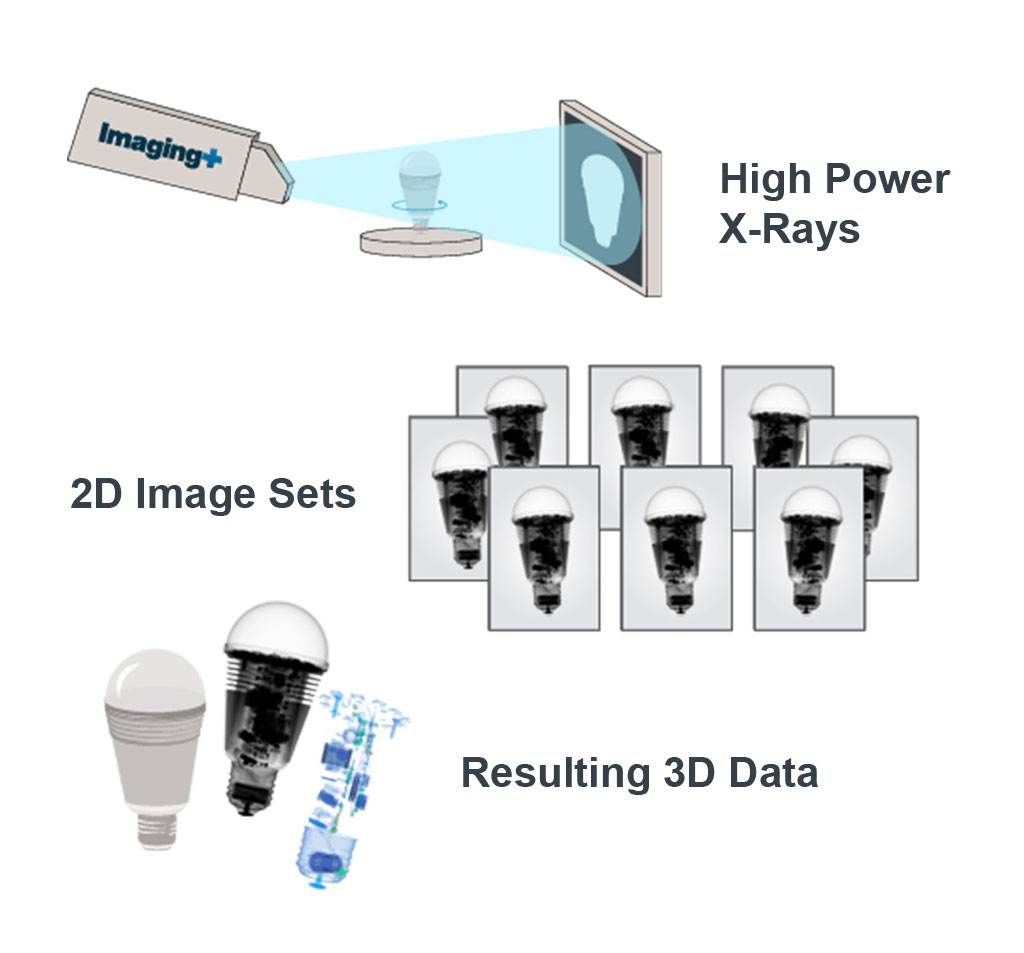

Industrial CT Scanning utilizes the same technology as medical diagnostic computed tomography, with a few major differences. In diagnostic computed tomography the patient lies stationary and the X-ray source and detectors rotate and move axially in a helical pattern, whereas in industrial CT the object being scanned rotates and moves axially while the X-ray source and detector remain fixed. In addition, industrial scanners utilize much more powerful X-rays than medical diagnostic machines, allowing the rays to penetrate plastic, wood, composite materials, and even metal.

With its higher power, 3D CT scans are capable of accurately defining internal and external features of parts, assemblies and products, both statically and over time, with possible resolutions down to one micron. Our unique 4D Imaging+ technology utilizes custom remote-controlled fixtures and software to actuate products and components during scans, enabling understanding of gears, mechanisms, fluids, particles and more. This technology is also able to evaluate complex multi-component parts to ensure proper manufacturing and assembly, and is very effective for inspecting welds and press fits in industries such as biomedical, aerospace, and automotive. As a leading industrial CT scanning service provider, Kinetic Vision is excited to offer this unique capability to our customers.

ISO 9001:2015 Certification

Kinetic Vision's industrial imaging group has ISO 9001:2015 certification, which is the world’s highest recognition for meeting quality standards. ISO 9001 is a quality management system that helps manufacturers and service providers ensure that they continue to meet customer satisfaction standards while striving to continually improve quality. In conjunction with this certification, our in-house quality processes govern machine calibration, technician training, data acquisition methods, data storage and data security.

Uses of Kinetic Vision's industrial CT scanning services include 3D CT Scanning, First Article Inspection, 3D Metrology, Failure Analysis, GD&T Analysis, 4D CT Scanning, Nanoscan, Porosity Analysis, Wall Thickness Analysis and Reverse Engineering Services.