Metrology Only

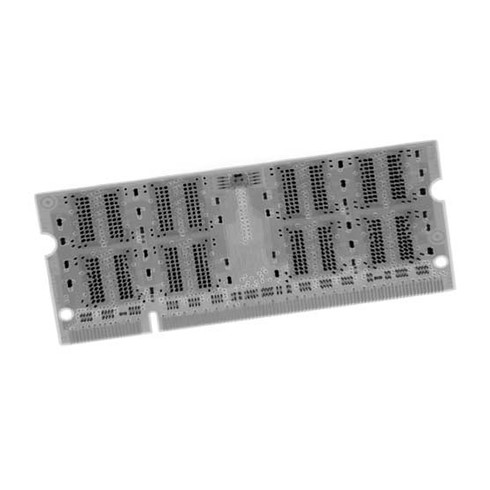

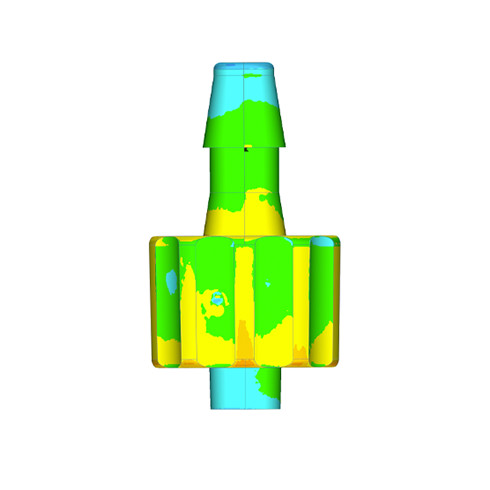

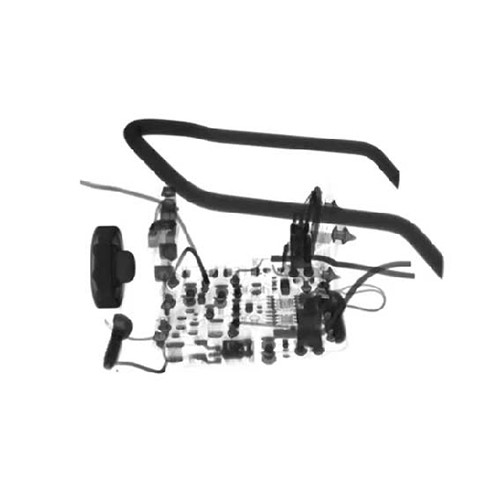

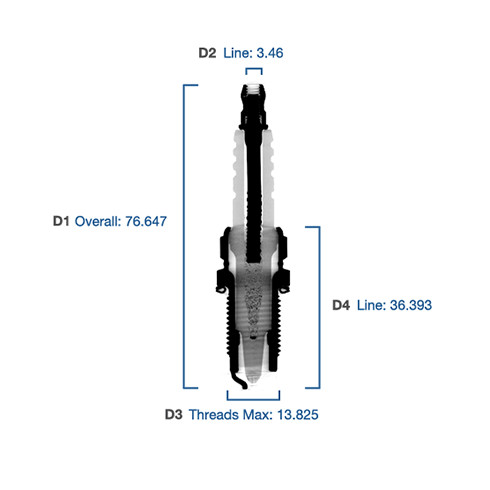

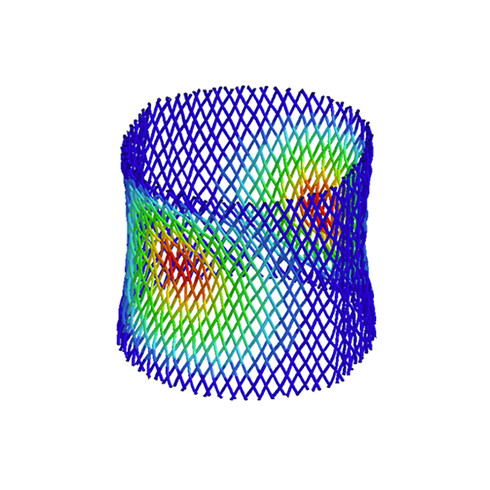

Our industrial scanning services utilize state-of-the-art imaging methodologies to design, measure, inspect and troubleshoot parts, products and systems. Our unique 4D Imaging+SM scanning technology enables you to analyze internal mechanisms, filters, pumps, linkages and other devices while they are functioning, allowing you to study motion, absorption, pressure, dispersion, porosity, and many other microscopic time-varying events. The result: a better understanding of the dimensionality and physics affecting your product's quality and performance. Uses include 3D Metrology, Failure Analysis, First Article Inspection (FAI), Reverse Engineering Services, Geometric Dimensioning and Tolerancing (GD&T), Industrial CT Scanning, Nanoscan and Porosity Analysis. We have helped hundreds of customers solve thousands of complex problems, and are proud to acknowledge our Metrology Group quality management system as ISO 9001:2015 certified.

Metrology Only

Our industrial scanning services utilize state-of-the-art imaging methodologies to design, measure, inspect and troubleshoot parts, products and systems. Our unique 4D Imaging+SM scanning technology enables you to analyze internal mechanisms, filters, pumps, linkages and other devices while they are functioning, allowing you to study motion, absorption, pressure, dispersion, porosity, and many other microscopic time-varying events. The result: a better understanding of the dimensionality and physics affecting your product's quality and performance. Uses include 3D Metrology, Failure Analysis, First Article Inspection (FAI), Reverse Engineering Services, Geometric Dimensioning and Tolerancing (GD&T), Industrial CT Scanning, Nanoscan and Porosity Analysis. We have helped hundreds of customers solve thousands of complex problems, and are proud to acknowledge our Metrology Group quality management system as ISO 9001:2015 certified.